Emulsifying Vertical Colloid Mill Peanut Butter Grinding Machine / Tomato Paste Making Machine

1. Application:

Daily chemical and cosmetics industry:

(1) baby cream, shaving cream, cream shampoo, toothpaste, cold cream, sunscreen cream, face cleanser, moisture cream, detergent, shampoo etc

Pharmacy industry:

(2) Emulsion, emulsifier, ointment, syrup etc

Food industry:

(3) sauce, cheese, oral syrup, nutrient solution, infant food, chocolate, saccharine etc

Chemical industry:

(4) latex, saponification, paint, resin, adhesives, lubricating agent etc

Technical parameter

| Model |

Main pot |

Water pot |

Oil pot |

Hydraulic lifting |

| Working volume |

Homogenizer

Power

|

Slow mixer power |

Vacuum pump power |

Working volume |

Mixer

power

|

Working volume |

Mixer

power

|

| ZL-10 |

10L |

1.1kw |

0.8kw |

0.75kw |

8L |

0.18kw |

5L |

0.18kw |

0.75kw |

| ZL-50 |

50L |

4-5.5kw |

0.75kw |

0.75kw |

40L |

0.2kw |

25L |

0.2kw |

0.75kw |

| ZL-100 |

100L |

5.5-7.5kw |

1.5kw |

1.5kw |

80L |

1.1kw |

50L |

1.1kw |

1.5kw |

| ZL-200 |

200L |

7.5-11kw |

2.2kw |

2.2kw |

160L |

1.5kw |

100L |

1.5kw |

1.5kw |

| ZL-300 |

300L |

11-15kw |

3kw |

2.2kw |

240L |

1.5-2.2kw |

150L |

1.5-2.2kw |

1.5kw |

| ZL-500 |

500L |

15-18.5kw |

5.5kw |

2.2kw |

400L |

3-4kw |

250L |

3-4kw |

2.2kw |

| ZL-1000 |

1000L |

18.5kw |

7.5kw |

3-4kw |

800L |

4-5.5kw |

500L |

4-5.5kw |

2.2kw |

2. ZL The machine is made up of pretreatment boiler (oil boiler, water boiler), vacuum emulsification blending boiler, vacuum pump , pouringout system, electric control system or steam heating system and workable .

3. The function of the machine including mixing, homogenizing, heating, emulsifier etc.

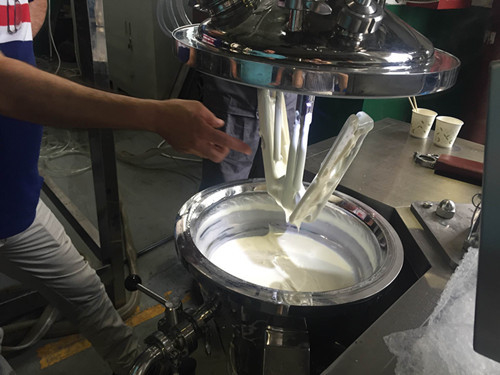

Vacuum emulsifying machines in our clents facotry as following:

That is very important choose us (Chasing machine)

|

No.

|

Name

|

brand

|

Remark

|

|

1

|

CPU

|

SIEMENS

|

Main control box

|

|

2

|

HMI

|

SIEMENS

|

Operation control box

|

|

3

|

Extension module

|

SIEMENS

|

main contorl box

|

|

4

|

Analog Modules

Digital modules

|

SIEMENS

|

main control box

|

|

5

|

CPU power modules

|

SIEMENS

|

main control box

|

|

6

|

Electrical components

|

France Schneider

|

control box

|

|

7

|

inveter

|

Panasonic and Siemens

|

main tank and oil/water phase boiler mixer ,homogenizer

|

|

8

|

motor

|

Germany's Siemens

|

homogenizer ,oil /water phase boiler motor

|

|

9

|

master switch

|

French Snyder

|

control box

|

|

10

|

24V power switch

|

Taiwan MEAN WELL

|

control box

|

|

11

|

Head Plate

|

Hokkai

|

main tank

|

|

12

|

Gear reducer

|

Shanghai matt

|

Main pot slow stirring

|

|

13

|

machinery seal

|

Germany's BGM

|

main tank and oil water phase mixer and homogenizer

|

|

14

|

Bearing

|

Japan NSK

|

stirring mechanism

|

|

15

|

oil seal

|

Japan NOK

|

stirring mechanism

|

|

16

|

vacuum pump

|

SIEMENS(Nash-eimo)

|

vacuum system

|

|

17

|

temperature sensor

|

German nine mau

|

inside the main tank ,oil phase boiler ,water phase boiler

|

|

18

|

electriomagnetic valve

|

Japan SMC

|

all pneumatic valves

|

|

19

|

Pneumatic Angle seat valve

|

USA Tektronix

|

heating ,cooling , Sewage

|

|

20

|

pneumatic butterfly

|

Shanghai YuanAn

|

oil water boiler discharge products

|

|

21

|

Traps

|

UK SpiraxSarco

|

steam heating

|

Reliability on top of above mentioned because the use of TRULY ORIGINAL REKNOWN BRANDS COMPONENTS is the guarantee of long lasting service life, no production rushes due to sudden unexpected downtime for a broken machine at the most needed moment.

Basic Functions: homogenize, mix, emulsify, heat and cool

Optional device:

i. Tank bottom installed homogenizer or inline homogenizer

ii. Mixing paddle type could be customized.

iii. Steam heating/ electric heating

iv. Manual valve/ automatic valve control

v. button control/ PLC control

vi. With rotor pump or not

vii. automatic load cell system or not

viii. CIP automatic clean

Packaging & Shipping

Wooden case.

Our Services

Pre-sale service:

Made up of several excellent sales engineers and focused on recommending and selecting suitable products for customers.

Technical support:

With a good background of education, many years of experience, provide the user with equipment confirmation, system project plan and technology update and product upgrade and other services.

Project manager:

Conduct order tracking and execute one-to-one service to customers until the product is delivered to customers.

Engineering services:

Fast and professional engineering installation and after-sales service team, ensure every equipment, every project can smoothly deliver users.

Our equipments in our clients factory

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!